The sustainability movement continues to grow and evolve. Individuals are more concerned than ever about the source of their foods, materials and products they purchase. This focus has caused many industries to look closely at their processes, products and byproducts – ultimately to improve themselves and improve the reputation of the organization as a whole.

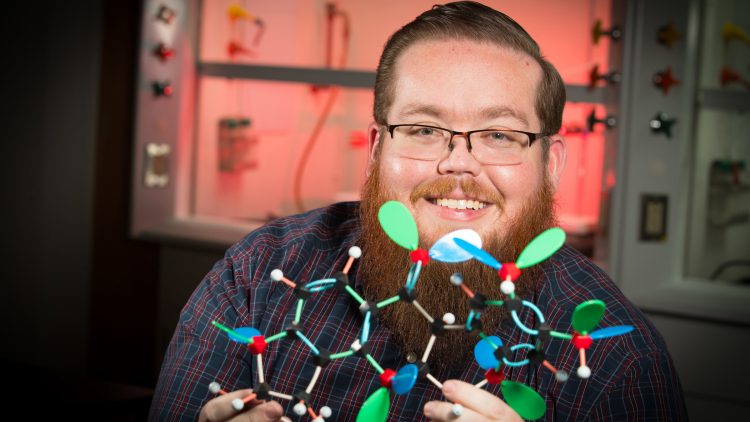

Dr. Matt Siebert, associate professor of chemistry at Missouri State University, shares about biodiesel and how it could change the way we get around.

“Biodiesel is a product of any fat or oil…take that fat or oil and you do a chemical reaction that changes the structure,” said Siebert. “There are actually reports of people going down to restaurants and purchasing or taking the waste fryer oil and doing that conversion at home. When you do that chemical conversion, you get what’s known as biodiesel and that can go into a conventional diesel engine, so your diesel car.”

This upcycling of a previously discarded byproduct seems like a good thing, but Siebert cautions that there’s a downside as well. It has a higher freezing point – so the fuel could freeze in the lines.

“If you put it into a conventional diesel engine that’s been running diesel fuel, some carbon deposits on the inside of your fuel lines,” and ultimately damages the engine, noted Siebert.

Due to these complications and since most passenger vehicles don’t run on diesel, Siebert and graduate students researched how to convert the biodiesel into gasoline.

“This gasoline would be chemically equivalent to petroleum-based gasoline. The major advantage is that the original source is from plants and so this would be a more sustainable fuel source than our current dependence on petroleum,” he added.

“What we want to know is under what conditions can you break that biodiesel down into gasoline products? We want to optimize things like the temperature and the pressure that are utilized to produce gasoline because that’s our ultimate target.”